What is SCADA anyway?

SCADA stands for Supervisory Control and Data Acquisition. It is a software and hardware system used to monitor, control, and automate industrial processes—either locally or across large distances.

SCADA systems collect real-time data from sensors and machines (like pumps, valves, robotic-systems or generators), process it through devices like RTUs (Remote Terminal Units) or PLCs (Programmable Logic Controllers), and present it to human operators through HMI's (Human-Machine Interfaces). Operators can then make informed decisions, adjust system behavior, or respond to alarms directly from a control center. SCADA systems come in a variety of different makes, models, sizes and configurations and is often custom tailored to the individual needs of the business. For example, meteorological monitoring stations (weather stations) make heavy use of data acquisition and so their SCADA is heavily tailored to store lots of historical data. In contrast, a factory that makes pastries, will have heavily utilize control equipment, and so their SCADA is tailored more for that purpose. Engineers, Technicians, Technologists, Mechanics, Electricians, and Operators all play an important part in the installation, maintenance, and operation of SCADA systems

SCADA's Primary Uses

SCADA is widely used in electric power utilities, where it monitors and controls substations, transmission lines, and grid stability in real time. It is essential in water and wastewater treatment plants, where it manages pumping stations, flow levels, and chemical dosing systems. In the oil and gas industry, SCADA systems oversee pipeline operations, monitor flow rates and pressures, and help detect leaks or failures across long distances. In Meteorology, SCADA systems collect massive amounts of weather data and process it so that transportation departments can make predictions about weather patterns and conduct storm planning,

In manufacturing and industrial automation, SCADA helps optimize production lines, monitor equipment performance, and reduce downtime through predictive maintenance. Transportation systems, such as railway signaling and traffic control centers, rely on SCADA to ensure safety and efficiency. Additionally, building management systems (BMS) and smart facilities use a SCADA-like system to control HVAC, lighting, and energy systems.

Overall, SCADA is used wherever complex processes require reliable, centralized supervision—often across geographically distributed assets.

The core functionality of SCADA (Supervisory Control and Data Acquisition) revolves around enabling efficient, real-time control and monitoring of industrial systems. SCADA systems integrate multiple components to automate, manage, and analyze complex processes, especially across large or distributed infrastructure.

At its core, SCADA performs five primary functions:

SCADA collects real-time data from field devices like sensors, meters, switches, and actuators. These inputs can include temperature, pressure, voltage, or flow rates, depending on the system being monitored.

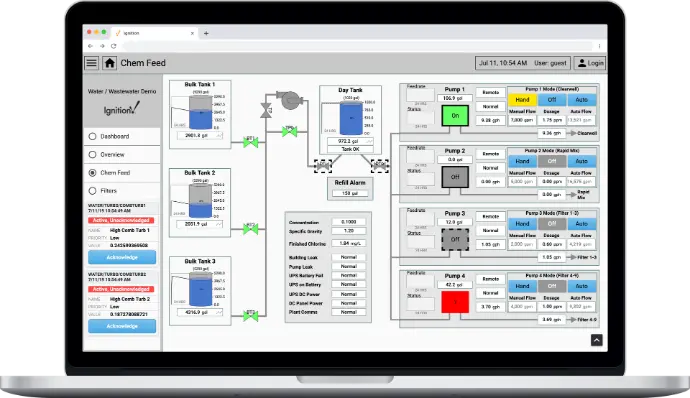

Operators use SCADA's Human-Machine Interface (HMI) to visualize the status of systems. The HMI displays data through dashboards, process diagrams, and live readouts, giving operators a full view of system performance.

SCADA systems allow remote or automated control of equipment. Operators can start or stop machines, open or close valves, adjust setpoints, or issue commands directly through the HMI interface.

SCADA systems trigger alerts when values exceed predefined thresholds or when faults occur. Alarms help operators quickly identify and respond to abnormal or unsafe conditions.

SCADA continuously logs system data for later analysis, compliance, maintenance planning, and performance evaluation. Historical trends can help diagnose problems, optimize operations, or ensure regulatory reporting.

What does a SCADA system look like?

Click on the items in the diagram to learn about their roles in a SCADA system